|

| Have a homebrew while you homebrew! |

It is time for another batch of homebrewed beer. Our

stout came out well, so this time we decided to try adapting a recipe for an IPA. The kicker here is that aside from rye, the beer is formulated to be a reddish color and uses brown sugar. I'm sorry to all the passionate brewers out there that brew pure malt, but we are pragmatic brewers here; the brown sugar doesn't even compose 10% of total fermentatable material. Without further ado, here is the recipe:

|

| Start by sanitizing and sterilizing everything |

Red Rye IPA

6 lbs Pale Malt Extract

8 oz Dry Malt Extract

8 oz Light Brown Sugar (15 minutes)

5 oz Corn Sugar (bottling)

1 lb 8 oz Rye Malt

8 oz Munich Malt

4 oz Roasted Barley

4 oz Crystal 20

1 oz Magnum (60 minutes)

.5 oz Columbus (30 min)

1 oz Willamette (5 minutes)

1 oz Willamette (dry hop; 7 days secondary)

.5 oz Columbus (dry hop; 7 days secondary)

|

| After 30 minutes of steeping |

I wanted to get a red color in our beer. Steeping and boiling gave the wort a blackish/brown color though, but we think that was from the sediment. My hypothesis was correct once we filtered some when we transferred the wort into the fermenter.

|

| Some early color prior to the boil |

|

| Getting that boil going |

|

| Chilling the wort |

|

| Siphoning the wort into the fermenter. |

One thing we might be concerned about is the inch of trub that has already appeared in the fermenter. I looked up some solutions to this phenomenon. Some people say that it makes no difference, while others say it can add to off flavors in the beer. I personally hope that not too much fermentatable sugar is trapped in the layers, as our yeast is top-fermenting.

|

| Primary fermentation |

|

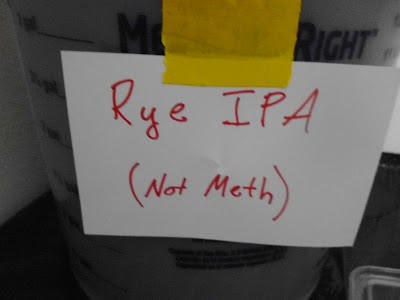

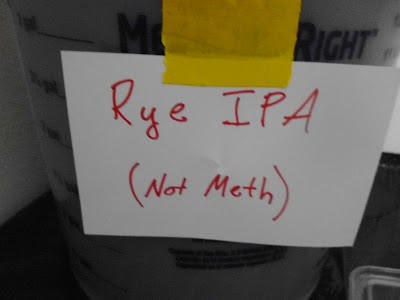

| A stern reminder |

Our original gravity was

1.064 (after adjustments for temperature). We estimate it ferments down to 1.018, giving an estimated ABV of 6%. We shall see in 2 weeks once primary fermentation is done. We sampled a bit of the wort and we were pleased with the character of the beer. Despite it being sweet (it'll all ferment out, we could definitely taste hoppy bitterness. As my roommate puts it, "I will enjoy this beer once it is done."

|

| Looks red to me (slightly cleared wort) |

UPDATE 5/17

Due to my time crunch coming up the next week, we decided to see if the beer was ready to rack and dry hop. Turns out, fermentation is complete. The final gravity is

1.016, meaning the beer is

6.3% ABV. Just as expected. It will sit for a week in secondary to pick up flavors from the dry hops we threw into it.

|

| Looks a lot more brown than expected |

|

| Racking away |

No comments:

Post a Comment

Hi folks, please only leave comments relative to the blog post. All spam will be removed and spammers will be blocked.

Note: Only a member of this blog may post a comment.